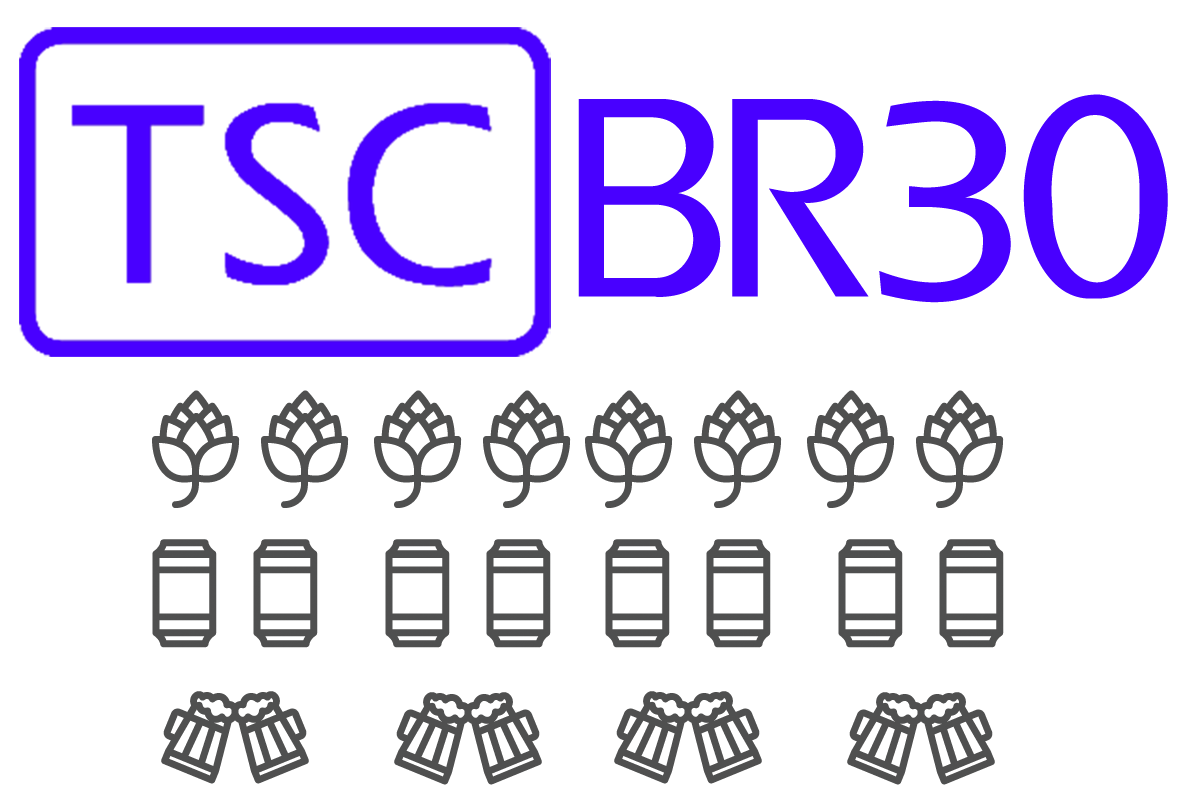

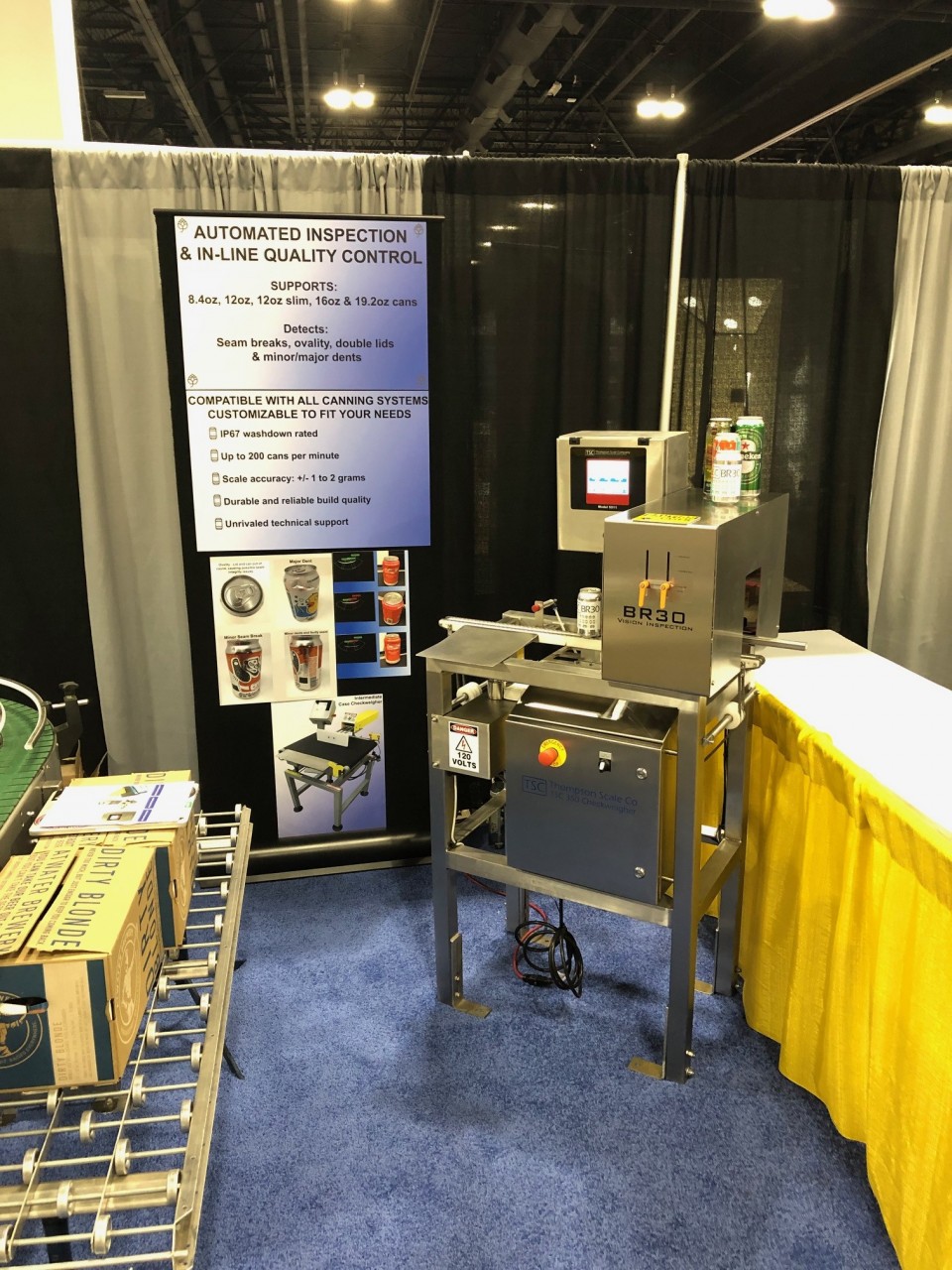

Packaging companies strive to increase productivity and efficiency while adhering to stringent quality standards, and one technology that has revolutionized this industry is the check weigher. Not only does this remarkable device ensure accurate weight measurement but it's also instrumental in streamlining operations, cutting costs, minimizing wast...

5811 Hits

5811 Hits