Checkweighers

Introduction

Unlike other Checkweigher Manufacturers, Thompson Scale’s machinery is made to last. Our core line of Checkweighers are built for many years of service, allowing our customers to run without constantly upgrading obsolete hardware or replacing mechanical parts every few months. We also offer world class tech support over the phone, free of charge. This shortens downtime and enables higher production runtime. Today we have dozens of checkweighers running in the field that were sold over 10 years ago, along with other hardware options sold 20 years ago. You can count on our reliability.

Tips on Selecting a Checkweigher Manufacturer

Five Things to Keep in Mind When Purchasing a Checkweigher

Checkweigher Core Models

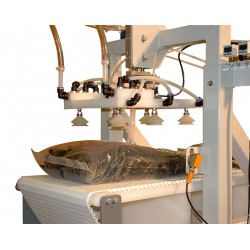

Heavy-Duty Checkweigher

Available in powder coated mild steel or all stainless steel for wash-down or corrosive environments. This checkweigher is rugged and provides highly accurate weight. The preferred checkweigher of the concrete, cement, salt and chemicals industries. Rates to 50/minute, accuracies to +/-20 g @ 2 Sigma and capacities to 1,000kg.

Heavy-Duty Checkweigher

Built for industrial and institutional packaging, this rugged and accurate belt conveyor scale is powered by a 3 Phase motorized drive roller to provide variable speed control when running smaller and larger packages.

...Learn MoreIntermediate Checkweigher

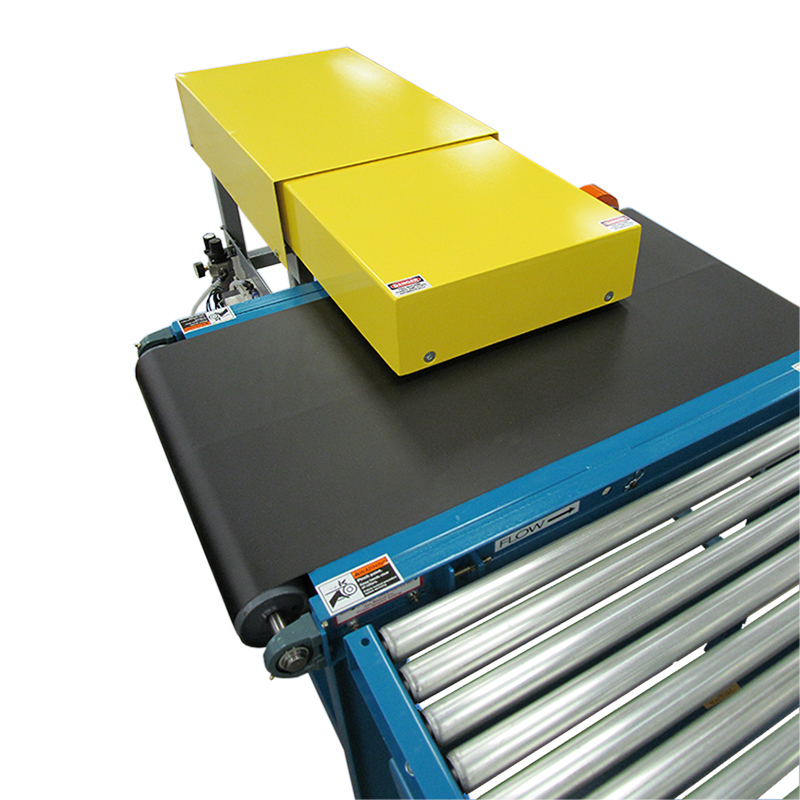

The preferred scale for case weighing and order fulfillment warehouses. Unlike our competitors, we build to meet your application needs, so a variety of conveyor sizes and heights are available. We build an all stainless steel wash-down rated version, as well as powder coated mild steel. Rates to 60/minute, accuracies to +/-9 g @ 2 Sigma and capacities to 22kg.

Intermediate Checkweigher

Designed for case and small bag weighing applications, the Intermediate offers belt style conveyors from 26” long to 36” long, and belt widths of 12” and 18”.

...Learn MoreKit Verifier

A smart and simple way to verify every package weight, automatically. Improve your productivity and eliminate shipping incorrect packages. Speed, Accuracy & Price. You get all 3.

Small Package

We weigh everything from explosives to brownies on this line of scales. Customized based upon 3 configurations, conveyors and scale capacities are designed to fit your exact application. We also offer optional metal detection. Controls are simple to use, and offer 3 levels of password protection. Reliable, high precision and backed by some of the best technical expertise around. Our high speed rates go up to 350/minute, accuracies to +/- 0.5 g @2 Sigma, and capacities to 10kg

TSC 350

for rigid packages-

- Weight range: Up to 10 lbs.

- Package sizes: Up to 12” dia./long

- Production rates: Up to 350/min

- Accuracies as high as +/-0.5g @ 2 Sigma

Sonic 350

for flexible and rigid package-

- Weight range: Up to 20 lbs.

- Package sizes: Up to 16” dia./long

- Production rates: Up to 220/min

- Accuracies as high as +/-0.5g @ 2 @Sigma

Custom

FAQ

What is a checkweigher?

Thompson Scale Co. manufactures in-motion checkweighers that weigh packaged products as they move down a production line. Our checkweigher controller monitors the weight output of a load cell mounted under a precision-built conveyor. The controls detect when a package enters and crosses the scale conveyor, and captures the weight just before the package exits the conveyor. The weight is displayed and can be used to determine if the package weight is acceptable or to be rejected.

Can the checkweigher stop to weigh a package?

Yes, we offer programming and motor controls to stop a package, weigh it, and allow the operator to hand adjust the weight. Once weight is within an acceptable range the operator presses a button to restart the conveyor. This works very well for open-mouth net weigh scales that are running rates below 10 bags per minute.

Does the scale conveyor need to be level?

We offer solutions with scale conveyors on an angle up to 12°, and can even accommodate in-feed and exit conveyors that are on different angles.

What checkweigher program is best for my application?

We offer a 3-zone and 5-zone checkweigher program that compares the package actual weight to a target weight and lower and upper reject limits. If the package weight is outside of the acceptable limits it is classified as reject. Another popular program is for manifest or order fulfillment applications. There is no target weight or reject limits. The package is weighed and the weight value transmitted out both the serial port and Ethernet TCP/IP port. Special programs for dual target weights are popular in the produce industry, for applications like weighing both a 3 lbs. bag and 5 lbs. bag of apples randomly on the same production line. Our sales and technical staff can help select the program best suited for your application.

How accurate is a checkweigher?

Scale accuracy is dependent upon the capacity of the scale and package being weighed. For example, our heavy-duty checkweigher uses a 500 lbs. load cell to support the 200 lbs. scale conveyor, and package weights up to 110 lbs. Best accuracy for this scale is +/-0.05 lbs. A scale for weighing a 1 lbs. bag of vegetables would most likely have a scale capacity of 10 kg, and can offer accuracies of +/-2 to 3 grams.

How many packages per minute will a checkweigher run?

This depends upon the package size and weight. For example our TSC 350 drag chain style checkweigher has a minimum weigh time requirement of just over 0.1 second for each package. Maximum rate for this scale is 350 packages per minute. At the other end of the spectrum is our Model 5511 heavy-duty checkweigher, with a minimum weigh time of 0.6 second and maximum rate of 60 per minute.

Is both a dynamic and static calibration required?

We require only a static calibration only. Calibration should be conducted using a known and precise weight. See the user’s manual for determining the proper weight size for your particular scale.

What size test weight is used for calibration?

There are two factors that determine the size test weight required. The first is based upon the actual capacity of the scale. There must be a load cell millivolt change of at least 3mV from the empty conveyor scale and that with the test weight applied. Secondly, the test weight must be greater than ½ the weight of the heaviest package to be run on the checkweigher. For the heavy-duty checkweigher, which is rated up to 110 lbs. package weights, we recommend a 50 lbs. test weight. This set the maximum weight rate at just about 120 lbs.

Does the checkweigher need recalibration for each product type?

No. Our static calibration sets the range for the scale, and any package size/weight can be run within the acceptable range. This range is determined by the amount of weigh time for the package. If the weigh time is too short, weights will not be repeatable or accurate. See the user’s manual for a table of weigh times based upon the type of checkweigher being used.

How do I check to see if the scale is working properly?

There are a couple tests. First verify the scale is calibrated and operating properly. Go to the Calibration screen, and select “Check Calibration”. Zero the display. The weight value should be stable and move only +/-1 or 2 increments. It should not drift away from zero, and should be stable when the scale conveyor is running. If the scale is not stable, contact Thompson Scale’s customer support for assistance.

From the run screen you can verify the operation of inputs and outputs. Touch the large weight value, top center on the screen. The bottom of the screen will change, showing 8 rectangles representing inputs, and 8 more representing outputs. You can verify if photo-eyes are working properly and see if the reject output is functioning when a reject weight occurs. There are also test routines within the “Tools” menu, under Configuration2

How do I change the load cell on a heavy-duty checkweigher?

The heavy-duty checkweigher is supplied with a flexure style scale with a 500 lbs. S-type load cell. NEVER CHANGE FROM UNDER THE SCALE. The scale conveyor must be removed, then the lid to the scale. A wire rope suspends the flexure assembly from the bottom of the load cell. Please read the section on load cell replacement found in our user’s manual, or call our customer support team for assistance.

Can I change the conveyor speed of the checkweigher?

Speeds can be changed on most of our scale conveyors, however caution should be exercised when doing so. Maximum conveyor speed is based on the length of your longest package and the length of the scale conveyor. If you run the conveyor too fast we will not have adequate weigh time and inaccurate weights will be generated. Contact the factory to discuss speed changes and we’ll advise on the best speed for your application.

What kind of reject signal does the checkweigher have?

The default configuration is output #8 for both low-weight and over-weight rejects. These signals can be separated within the configuration menu. The checkweigher controller also has an input dedicated to an up-stream device, like a barcode reader or metal detector. If that device detects a reject it drives this input on, and the checkweigher controller manages timing for rejection of that package. All reject signals have a delay timer, from when the package is weighed to when it is at the reject device, and a duration timer, to set how long to actuate the reject device. This set of timers can be set to 0.00 second delay and a duration of 0.30 second, when interfacing with a PLC that in turn operates the reject device.

What kind of data is available?

Data is transmitted via RS-232, RS-422 and Ethernet TCP/IP. By default we always transmit the weight value. Other data fields that can be enabled include time/date stamp, pass/fail bit, total units, and target weight and lower and upper reject values. Data is transmitted as weights occur, and are not stored in a file for later download.

We also offer an Ethernet IP port as a purchase option. This EIP port interfaces directly with Allen-Bradley’s line of PLCs, and gives the user total access to all configuration and data settings within the checkweigher controller. The user can create and upload recipes and monitor data and health of the checkweigher.

How do I collect data from the checkweigher?

We offer a few choices for data logging. The #930 data logger is the least expensive option, and is hardwired to the serial port within the checkweigher controller. Weights are logged to a thumb drive that the user can then remove and load into their PC. The data files are in a CSV format, so are compatible with spreadsheet programs.

SPPC Lite is a software solution that loads on the user’s PC and connects to the scale controller via their TPC/IP network. See more about SPPC Lite here.

StatPak-PC II is our most highly-integrated data logging and reporting software solution. Read more about it here.

Are Checkweigher menus in different languages?

Yes, we offer English as the default, and have Spanish (Mexico) and French (Canada) as options.

How do I troubleshoot the scale’s load cell?

You will need an electrical multi-meter that can read millivolts (mV). First, set the meter to volts DC, and measure at the load cell connector in the checkweigher controller. Measure between +EX and –EX. This reading should be precisely 10VDC. If it is not, contact the factory.

Set the meter to mV, and measure between +SIG and –SIG. This value will be dependent upon the capacity of the scale and style of checkweigher. It should be mid-range of the load cells total capacity, or between 9 and 17mV. A load cell rated at 2mV/V has a maximum range of 20mV, so any reading over 20mV shows the load cell is damaged. Other load cells are rated at 3mV/V, so max. range is 30mV.