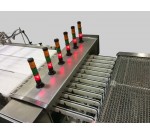

Multi-Lane Checkweighers

Description

Configurations from 2 to 16 lane are built to meet your specific needs. Available configurations include drag chain, belt conveyor and gravity assisted fixed scale designs. Flexible and rigid packaging, close centerlines and limited footprint are considered for each application. Use of standardized and readily available load cells provide solid performance and keep cost of ownership low.

Many options for rejection and identifying off-weight packages.

Color touch screen scale controls hold 100 recipes in memory, user-set for 3 or 5 zone (low reject, low pass, good, high pass & high reject) outputs. 3-level password protection, audit trail for calibrations.

Ethernet TCP/IP, RS-232 and RS-422 built in. Variety of data formats, connections for data logging and outputs to remote digital displays or HMI interfaces. Optional Ethernet IP and Modbus interfaces available.

Performance & Uses

Our multi-lane checkweighers perform with rates of up to 150 packages per minute, per lane, with accuracies as high as +/- 1-2g @ 2 Sigma. Scale capacities application dependent. Our multiple lane systems can be used for prepared food trays, cookies, candies, baked goods, and machined parts.

What sets us apart

- We provide rugged, accurate equipment built to meet your specific production line needs

- Simple, single static calibration for your range of products

- Fairly priced spare parts

- Standard load cells, available from multiple sources

- Superior customer support

- Independent service affiliates across North America

coming soon

coming soon